AL176

HOLI

CE OIML NTEP RoHS

| Availability: | |

|---|---|

| Quantity: | |

Precision and performance in the world of weighing instruments have a new name: the AL176 load cell by HOLI Scale. As industries constantly seek to push the envelope, the AL176 stands as an epitome of advanced weighing engineering, setting itself apart even from its commendable counterpart, the AL174.

Redefining Capacity

The most striking feature of the AL176 is its mammoth weighing capability. With an ability to support up to a whopping 2000kg, the AL176 is twice as capable as the AL174, which has a maximum capacity of 750kg. Such a leap in capacity means the AL176 can cater to larger industrial applications, handling substantial weights with precision.

Craftsmanship in Aluminium

Like its sibling, the AL174, the AL176 is crafted from top-notch aluminium, ensuring its longevity and consistent performance. However, its reinforced design elements further ensure that the AL176 can effectively bear and measure higher loads without compromising on accuracy.

Why AL176 Stands Out

When comparing the AL174 and AL176, the pronounced difference lies in their capacity. While the AL174 is exceptional for a myriad of applications, the AL176 is tailored for industries that require weighing massive items with the assurance of precise readings.

Unwavering Precision

Despite its expansive capacity, the AL176 retains the hallmark of high accuracy that HOLI Scale is renowned for. Industries ranging from heavy manufacturing to large-scale logistics can now bank on the AL176 for dependable results every time.

Conclusion

The AL176 load cell is more than just an advancement; it's a revolution. It signifies HOLI Scale's commitment to catering to every industrial need, no matter how expansive. For those who believe in pushing boundaries and settling for nothing but the best, the AL176 is the ultimate weighing companion.

| Specifications | ||||||

| Parameter | Value | Units | ||||

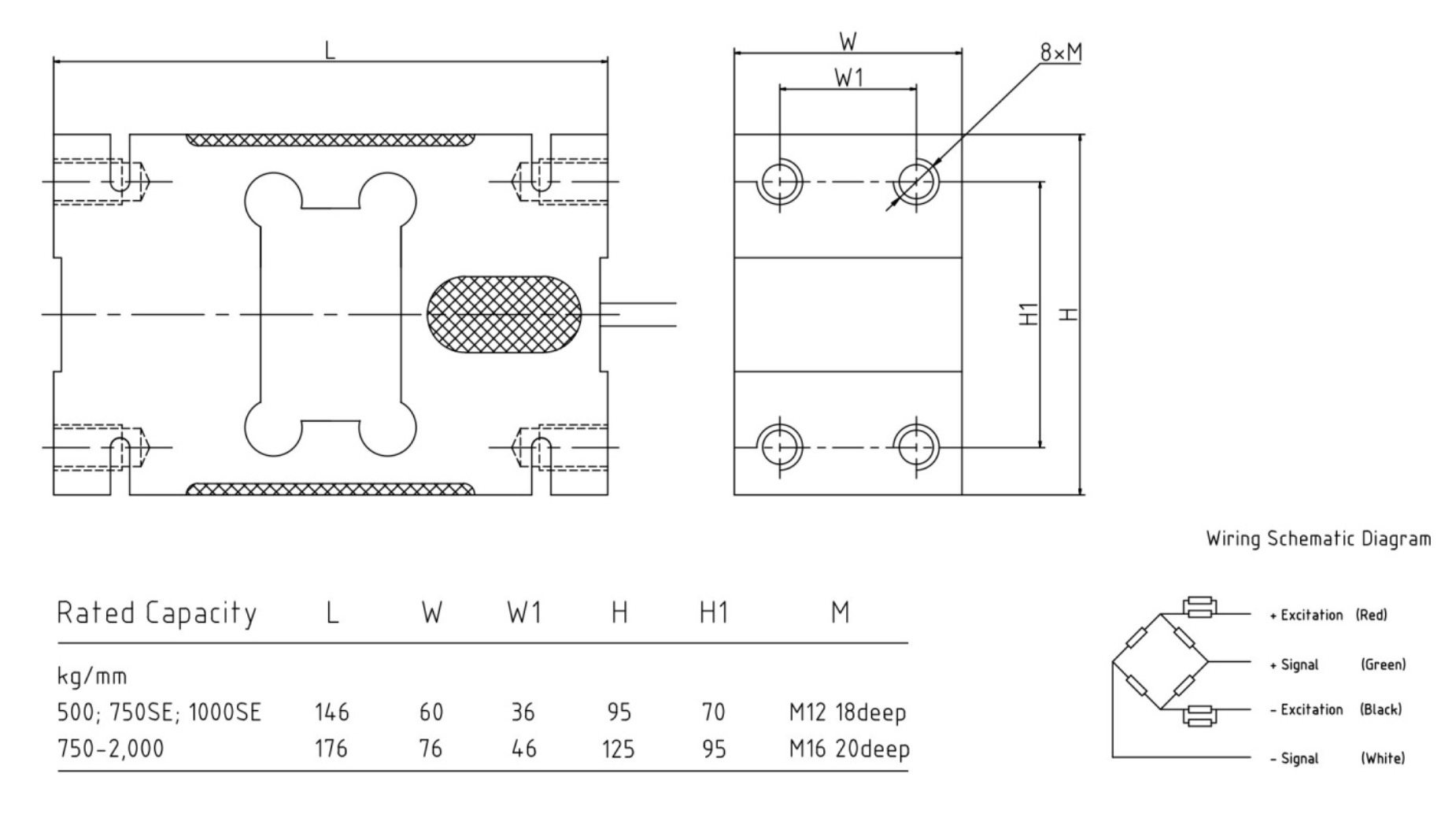

| Rated capacity (Emax) | 500 / 750 / 1000 / 2000 | kg | ||||

| Accuracy class | C3 | C3MR | C6 | |||

| Maximum number of LC intervals (nmax) | 3000 | 2*3000 | 6000 | |||

| Min. LC verification interval (vmin) | Emax/5000 | Emax/10000 | g | |||

| Temp. effect on zero balance | ± 0.0028 | ± 0.0014 | % of Emax/℃ | |||

| Zero balance | ± 0.1 | mV/V | ||||

| Rated output | 2.0 | mV/V | ||||

| Rated output tolerance | ± 0.2 | mV/V | ||||

| Temp. effect on rated output +20…+40℃ | ± 0.00175 | ± 0.00175 | ± 0.00131 | % of AL/℃ | ||

| -10…+20℃ | ± 0.00117 | ± 0.00117 | ± 0.00088 | |||

| Hysteresis error | ± 0.0175 | ± 0.0175 | ± 0.0105 | % of Emax | ||

| Non-linearity error | ± 0.0175 | ± 0.0175 | ± 0.0105 | % of Emax | ||

| Min. dead load output return | ± 0.0166 | ± 0.0166 | ± 0.0125 | % of AL | ||

| Offer center load error(OIML R76) | ± 0.0044 | ± 0.0044 | ± 0.0026 | % of AL/cm | ||

| Terminal resistance | Excitation | 404 ± 15 | Ω | |||

| Output | 350 ± 3 | Ω | ||||

| Insulation resistance @50VDC | >2000 | MΩ | ||||

| Excitation voltage | Recommended | 10 | V AC/DC | |||

| Maximum | 15 | V AC/DC | ||||

| Temperature range | Compensated | -10 to +40 | ℃ | |||

| Operating | -10 to +50 | ℃ | ||||

| Safe storage | -25 to +70 | ℃ | ||||

| Load limit | Safe | 150 | % of Emax | |||

| Ultimate | 300 | % of Emax | ||||

| Protection | Type | Silicone rubber over gage | ||||

| IP rating | IP65 | |||||

| OIML / European Approval | OIML Cert. No | R60-2017-A-NL1-21.06 | ||||

| European Cert. No. | TC11566 | |||||

| Class | C6 | |||||

| nmax | 6000 | |||||

| NTEP Approval | Cert. No. | 23-029 | ||||

| Class | III | |||||

| nmax | 6000 | |||||

| Cable | Length | 2.5 | m | |||

| Type | 4-wire, PVC | |||||

| Diameter | Φ6 | |||||

| Construction | Aluminum | |||||

| Maximum platform size | 1200 x 1200 | mm | ||||

| Recommended torque | up to 1000kg: 98 / 2000kg: 140 | N.m | ||||

| Notes: The values for linearity, hysteresis and temp. effect on rated output are recommended values, the sum of these data meets the requirements according to OIML R60. | ||||||

Precision and performance in the world of weighing instruments have a new name: the AL176 load cell by HOLI Scale. As industries constantly seek to push the envelope, the AL176 stands as an epitome of advanced weighing engineering, setting itself apart even from its commendable counterpart, the AL174.

Redefining Capacity

The most striking feature of the AL176 is its mammoth weighing capability. With an ability to support up to a whopping 2000kg, the AL176 is twice as capable as the AL174, which has a maximum capacity of 750kg. Such a leap in capacity means the AL176 can cater to larger industrial applications, handling substantial weights with precision.

Craftsmanship in Aluminium

Like its sibling, the AL174, the AL176 is crafted from top-notch aluminium, ensuring its longevity and consistent performance. However, its reinforced design elements further ensure that the AL176 can effectively bear and measure higher loads without compromising on accuracy.

Why AL176 Stands Out

When comparing the AL174 and AL176, the pronounced difference lies in their capacity. While the AL174 is exceptional for a myriad of applications, the AL176 is tailored for industries that require weighing massive items with the assurance of precise readings.

Unwavering Precision

Despite its expansive capacity, the AL176 retains the hallmark of high accuracy that HOLI Scale is renowned for. Industries ranging from heavy manufacturing to large-scale logistics can now bank on the AL176 for dependable results every time.

Conclusion

The AL176 load cell is more than just an advancement; it's a revolution. It signifies HOLI Scale's commitment to catering to every industrial need, no matter how expansive. For those who believe in pushing boundaries and settling for nothing but the best, the AL176 is the ultimate weighing companion.

| Specifications | ||||||

| Parameter | Value | Units | ||||

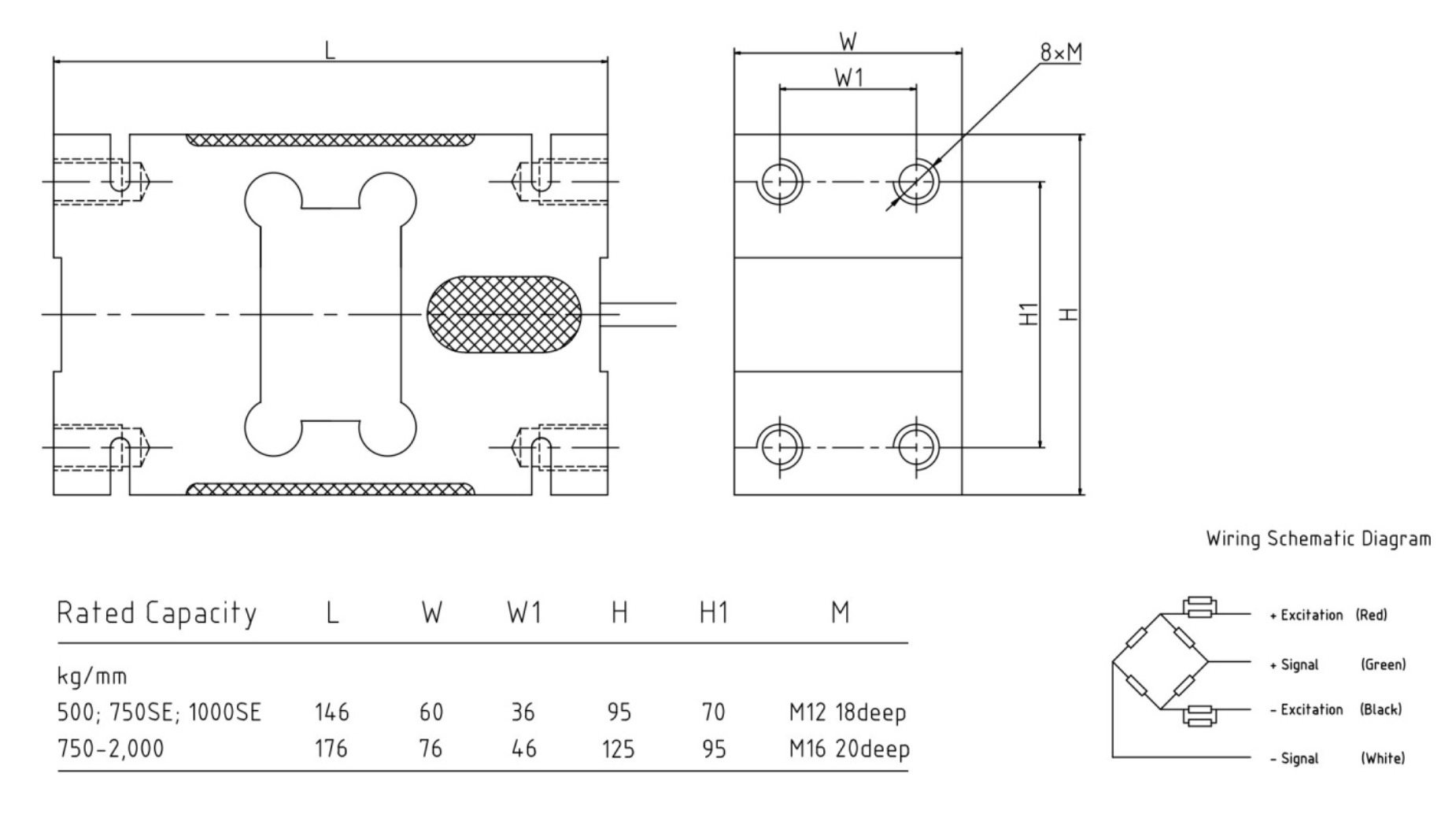

| Rated capacity (Emax) | 500 / 750 / 1000 / 2000 | kg | ||||

| Accuracy class | C3 | C3MR | C6 | |||

| Maximum number of LC intervals (nmax) | 3000 | 2*3000 | 6000 | |||

| Min. LC verification interval (vmin) | Emax/5000 | Emax/10000 | g | |||

| Temp. effect on zero balance | ± 0.0028 | ± 0.0014 | % of Emax/℃ | |||

| Zero balance | ± 0.1 | mV/V | ||||

| Rated output | 2.0 | mV/V | ||||

| Rated output tolerance | ± 0.2 | mV/V | ||||

| Temp. effect on rated output +20…+40℃ | ± 0.00175 | ± 0.00175 | ± 0.00131 | % of AL/℃ | ||

| -10…+20℃ | ± 0.00117 | ± 0.00117 | ± 0.00088 | |||

| Hysteresis error | ± 0.0175 | ± 0.0175 | ± 0.0105 | % of Emax | ||

| Non-linearity error | ± 0.0175 | ± 0.0175 | ± 0.0105 | % of Emax | ||

| Min. dead load output return | ± 0.0166 | ± 0.0166 | ± 0.0125 | % of AL | ||

| Offer center load error(OIML R76) | ± 0.0044 | ± 0.0044 | ± 0.0026 | % of AL/cm | ||

| Terminal resistance | Excitation | 404 ± 15 | Ω | |||

| Output | 350 ± 3 | Ω | ||||

| Insulation resistance @50VDC | >2000 | MΩ | ||||

| Excitation voltage | Recommended | 10 | V AC/DC | |||

| Maximum | 15 | V AC/DC | ||||

| Temperature range | Compensated | -10 to +40 | ℃ | |||

| Operating | -10 to +50 | ℃ | ||||

| Safe storage | -25 to +70 | ℃ | ||||

| Load limit | Safe | 150 | % of Emax | |||

| Ultimate | 300 | % of Emax | ||||

| Protection | Type | Silicone rubber over gage | ||||

| IP rating | IP65 | |||||

| OIML / European Approval | OIML Cert. No | R60-2017-A-NL1-21.06 | ||||

| European Cert. No. | TC11566 | |||||

| Class | C6 | |||||

| nmax | 6000 | |||||

| NTEP Approval | Cert. No. | 23-029 | ||||

| Class | III | |||||

| nmax | 6000 | |||||

| Cable | Length | 2.5 | m | |||

| Type | 4-wire, PVC | |||||

| Diameter | Φ6 | |||||

| Construction | Aluminum | |||||

| Maximum platform size | 1200 x 1200 | mm | ||||

| Recommended torque | up to 1000kg: 98 / 2000kg: 140 | N.m | ||||

| Notes: The values for linearity, hysteresis and temp. effect on rated output are recommended values, the sum of these data meets the requirements according to OIML R60. | ||||||