AL130

HOLI

CE OIML NTEP RoHS

| Availability: | |

|---|---|

| Quantity: | |

HOLI Scale, a renowned name in the weighing industry, proudly presents the AL130 Load Cell – a testament to innovation, quality, and precision.

Why Choose the AL130 Load Cell?

1. Superior Material: Crafted from high-quality aluminum, the AL130 ensures not only durability but also lightweight handling, making it a top choice for various applications.

2. Single Point Design: The single-point design of the AL130 load cell makes it perfect for platform scales and other weighing applications where distributed loads are expected. This design aids in providing consistent readings, even with off-center loads.

3. Optimal Capacity Range: The AL130 offers a range of capacities to suit different weighing needs. Whether for industrial, commercial, or experimental purposes, this load cell stands out in versatility.

4. OIML/NTEP Certified: Confidence in the AL130 is not just based on our word; it's backed by its OIML/NTEP certification, affirming its compliance with international standards.

5. Designed for Excellence: With HOLI Scale's dedication to continuous research and development, users can be assured that they are investing in a product that represents the forefront of weighing technology.

6. Easy Integration: The AL130 load cell is designed for seamless integration into existing systems, reducing the hassle of setup and ensuring compatibility with a range of equipment.

In an age where precision and reliability can mean the difference between average and excellence, the AL130 Load Cell by HOLI Scale is the trusted partner every weighing application needs. Experience accuracy like never before. Choose AL130.

| Specifications | |||||||

| Parameter | Value | Units | |||||

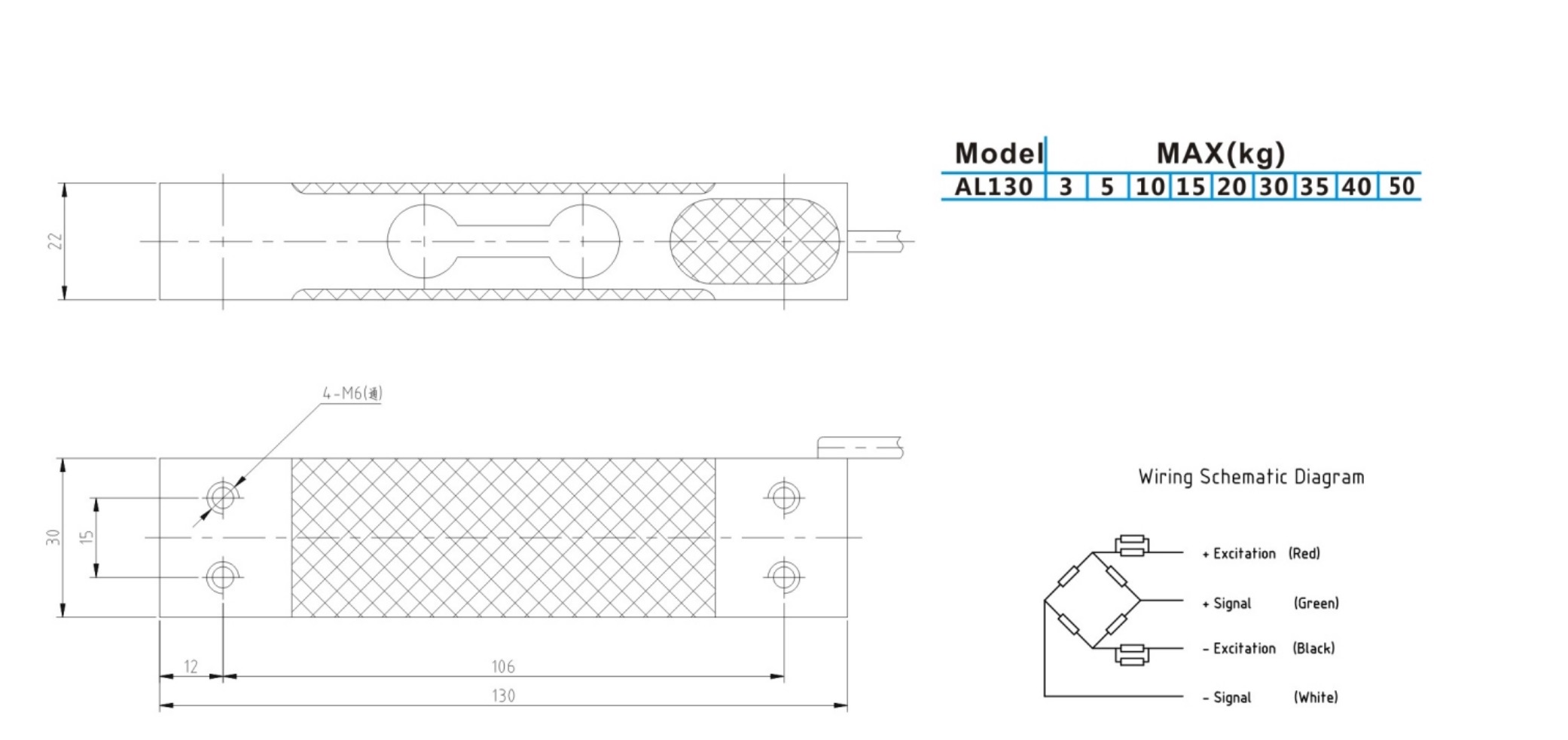

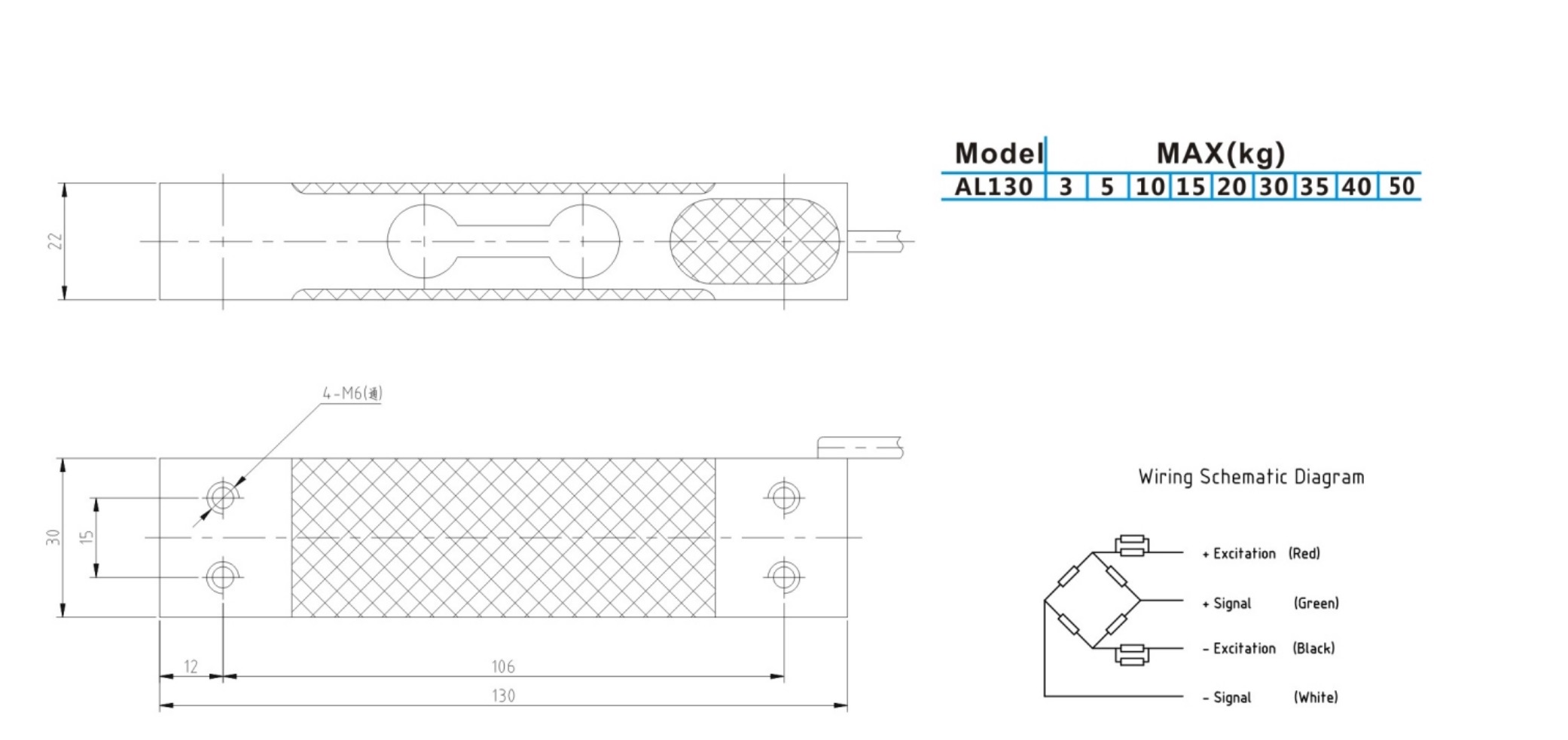

| Rated capacity (Emax) | 3 / 5 / 10 / 15 / 20 / 30 / 50 | kg | |||||

| Accuracy class | C3 | C3MR | C5 | C6 | |||

| Maximum number of LC intervals (nmax) | 3000 | 2*3000 | 5000 | 6000 | |||

| Min. LC verification interval (vmin) | Emax/5000 | Emax/10000 | g | ||||

| Temp. effect on zero balance | ± 0.0028 | ± 0.0014 | % of Emax/℃ | ||||

| Zero balance | ± 0.1 | mV/V | |||||

| Rated output | 2.0 | mV/V | |||||

| Rated output tolerance | ± 0.2 | mV/V | |||||

| Temp. effect on rated output +20…+40℃ | ± 0.00175 | ± 0.00175 | ± 0.00105 | ± 0.00087 | % of AL/℃ | ||

| -10…+20℃ | ± 0.00117 | ± 0.00117 | ± 0.0007 | ± 0.00058 | |||

| Hysteresis error | ± 0.0175 | ± 0.0175 | ± 0.0105 | ± 0.0105 | % of Emax | ||

| Non-linearity error | ± 0.0175 | ± 0.0175 | ± 0.0105 | ± 0.0105 | % of Emax | ||

| Min. dead load output return | ± 0.0166 | ± 0.0166 | ± 0.0100 | ± 0.0083 | % of AL | ||

| Offer center load error(OIML R76) | ± 0.0044 | ± 0.0044 | ± 0.0026 | ± 0.0022 | % of AL/cm | ||

| Terminal resistance | Excitation | 404 ± 15 | Ω | ||||

| Output | 350 ± 3 | Ω | |||||

| Insulation resistance @50VDC | >2000 | MΩ | |||||

| Excitation voltage | Recommended | 10 | V AC/DC | ||||

| Maximum | 15 | V AC/DC | |||||

| Temperature range | Compensated | -10 to +40 | ℃ | ||||

| Operating | -10 to +50 | ℃ | |||||

| Safe storage | -25 to +70 | ℃ | |||||

| Load limit | Safe | 150 | % of Emax | ||||

| Ultimate | 300 | % of Emax | |||||

| Protection | Type | Silicone rubber over gage | |||||

| IP rating | IP65 | ||||||

| OIML / European Approval | OIML Cert. No. | R60-2017-A-NL1-22.21 | |||||

| European Cert. No. | TC11563 | ||||||

| Class | 3-30kg, C4.5; 30-50kg, C6. | ||||||

| nmax | 3-30kg, 4500; 30-50kg, 6000. | ||||||

| NTEP Approval | Cert. No. | 23-028 | |||||

| Class | III | ||||||

| nmax | 6000 | ||||||

| Cable | Length | 1.5 | m | ||||

| Type | 4-wire, PVC | ||||||

| Diameter | Φ4 | ||||||

| Construction | Aluminum | ||||||

| Maximum platform size | 250 x 300 for 3 to 10kg; 300 x 350 for 20 to 50kg | mm | |||||

| Recommended torque | 10.0 | N.m | |||||

| Notes: The values for linearity, hysteresis and temp. effect on rated output are recommended values, the sum of these data meets the requirements according to OIML R60. | |||||||

HOLI Scale, a renowned name in the weighing industry, proudly presents the AL130 Load Cell – a testament to innovation, quality, and precision.

Why Choose the AL130 Load Cell?

1. Superior Material: Crafted from high-quality aluminum, the AL130 ensures not only durability but also lightweight handling, making it a top choice for various applications.

2. Single Point Design: The single-point design of the AL130 load cell makes it perfect for platform scales and other weighing applications where distributed loads are expected. This design aids in providing consistent readings, even with off-center loads.

3. Optimal Capacity Range: The AL130 offers a range of capacities to suit different weighing needs. Whether for industrial, commercial, or experimental purposes, this load cell stands out in versatility.

4. OIML/NTEP Certified: Confidence in the AL130 is not just based on our word; it's backed by its OIML/NTEP certification, affirming its compliance with international standards.

5. Designed for Excellence: With HOLI Scale's dedication to continuous research and development, users can be assured that they are investing in a product that represents the forefront of weighing technology.

6. Easy Integration: The AL130 load cell is designed for seamless integration into existing systems, reducing the hassle of setup and ensuring compatibility with a range of equipment.

In an age where precision and reliability can mean the difference between average and excellence, the AL130 Load Cell by HOLI Scale is the trusted partner every weighing application needs. Experience accuracy like never before. Choose AL130.

| Specifications | |||||||

| Parameter | Value | Units | |||||

| Rated capacity (Emax) | 3 / 5 / 10 / 15 / 20 / 30 / 50 | kg | |||||

| Accuracy class | C3 | C3MR | C5 | C6 | |||

| Maximum number of LC intervals (nmax) | 3000 | 2*3000 | 5000 | 6000 | |||

| Min. LC verification interval (vmin) | Emax/5000 | Emax/10000 | g | ||||

| Temp. effect on zero balance | ± 0.0028 | ± 0.0014 | % of Emax/℃ | ||||

| Zero balance | ± 0.1 | mV/V | |||||

| Rated output | 2.0 | mV/V | |||||

| Rated output tolerance | ± 0.2 | mV/V | |||||

| Temp. effect on rated output +20…+40℃ | ± 0.00175 | ± 0.00175 | ± 0.00105 | ± 0.00087 | % of AL/℃ | ||

| -10…+20℃ | ± 0.00117 | ± 0.00117 | ± 0.0007 | ± 0.00058 | |||

| Hysteresis error | ± 0.0175 | ± 0.0175 | ± 0.0105 | ± 0.0105 | % of Emax | ||

| Non-linearity error | ± 0.0175 | ± 0.0175 | ± 0.0105 | ± 0.0105 | % of Emax | ||

| Min. dead load output return | ± 0.0166 | ± 0.0166 | ± 0.0100 | ± 0.0083 | % of AL | ||

| Offer center load error(OIML R76) | ± 0.0044 | ± 0.0044 | ± 0.0026 | ± 0.0022 | % of AL/cm | ||

| Terminal resistance | Excitation | 404 ± 15 | Ω | ||||

| Output | 350 ± 3 | Ω | |||||

| Insulation resistance @50VDC | >2000 | MΩ | |||||

| Excitation voltage | Recommended | 10 | V AC/DC | ||||

| Maximum | 15 | V AC/DC | |||||

| Temperature range | Compensated | -10 to +40 | ℃ | ||||

| Operating | -10 to +50 | ℃ | |||||

| Safe storage | -25 to +70 | ℃ | |||||

| Load limit | Safe | 150 | % of Emax | ||||

| Ultimate | 300 | % of Emax | |||||

| Protection | Type | Silicone rubber over gage | |||||

| IP rating | IP65 | ||||||

| OIML / European Approval | OIML Cert. No. | R60-2017-A-NL1-22.21 | |||||

| European Cert. No. | TC11563 | ||||||

| Class | 3-30kg, C4.5; 30-50kg, C6. | ||||||

| nmax | 3-30kg, 4500; 30-50kg, 6000. | ||||||

| NTEP Approval | Cert. No. | 23-028 | |||||

| Class | III | ||||||

| nmax | 6000 | ||||||

| Cable | Length | 1.5 | m | ||||

| Type | 4-wire, PVC | ||||||

| Diameter | Φ4 | ||||||

| Construction | Aluminum | ||||||

| Maximum platform size | 250 x 300 for 3 to 10kg; 300 x 350 for 20 to 50kg | mm | |||||

| Recommended torque | 10.0 | N.m | |||||

| Notes: The values for linearity, hysteresis and temp. effect on rated output are recommended values, the sum of these data meets the requirements according to OIML R60. | |||||||